warehouse rfid tags In a warehouse environment, RFID tags can be attached to individual items, boxes, or pallets. RFID readers located at various points within the warehouse read the data contained in the tags, and the system then processes this information to help companies track inventory in real-time. $21.76

0 · rfid warehouse tracking system

1 · rfid warehouse tracking

2 · rfid warehouse management system requirements

3 · rfid warehouse inventory system

4 · rfid system for warehouse management

5 · rfid for warehouse inventory

6 · rfid based warehouse management system

7 · how rfid works in warehouse

For the purpose of this tutorial, we’ll show you how to use program an NFC tag by using the NFC Tools app, but you can also use NFC TagWriter, and the steps will be similar. Here’s what you.

Learn how to efficiently implement an RFID smart warehouse setup to optimize inventory .

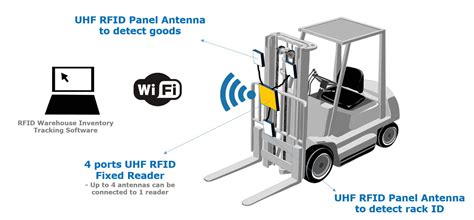

Learn how to efficiently implement an RFID smart warehouse setup to optimize inventory management, reduce costs, and boost productivity.RFID tags can tell you when items come in to or leave the warehouse: In addition to that, they can also tell you where items are located inside of the warehouse. RFID readers can be placed at entrances and exits to your facility, allowing real-time tracking of inventory as it moves in and out of your warehouse.With an RFID warehouse management tracking system, items can be scanned and catalogued from anywhere, even when they’re hidden behind boxes or pallets. RFID tags can also be detected and read remotely and simultaneously.

In a warehouse environment, RFID tags can be attached to individual items, boxes, or pallets. RFID readers located at various points within the warehouse read the data contained in the tags, and the system then processes this information to help companies track inventory in real-time. A comprehensive guide to RFID for warehouse operations management. 08 August 2022. 9 min read. Radio Frequency Identification (RFID) refers to a wireless system comprised of two components: tags and readers. Operational efficiency stands at the core of successful warehouse management, and RFID technology serves as a catalyst in this domain. The instantaneous data capture from RFID tags bypasses the need for manual data entry, . RFID tags can be attached to high-value items, and the system can immediately detect unauthorized movement. This feature acts as a deterrent for potential thieves and helps maintain the integrity of the warehouse. Challenges in .

By using RFID tags to track items, warehouses can improve their efficiency and accuracy. This guide will teach you how to decide if an RFID system is appropriate for your warehouse and how to implement it successfully.Tags, labels, and inlays are the fundamental building block of any RFID solution. Between passive or active, a range of frequencies, label specs, and environmental conditions there is a lot to evaluate when finding the right label. Learn More. RFID tags and label products are becoming increasingly popular for warehouse management as a way to maintain control of your inventory. What is RFID? Radio-frequency identification (RFID) uses electromagnetic fields to automatically identify and track tags and labels attached to objects.

Learn how to efficiently implement an RFID smart warehouse setup to optimize inventory management, reduce costs, and boost productivity.RFID tags can tell you when items come in to or leave the warehouse: In addition to that, they can also tell you where items are located inside of the warehouse. RFID readers can be placed at entrances and exits to your facility, allowing real-time tracking of inventory as it moves in and out of your warehouse.With an RFID warehouse management tracking system, items can be scanned and catalogued from anywhere, even when they’re hidden behind boxes or pallets. RFID tags can also be detected and read remotely and simultaneously.In a warehouse environment, RFID tags can be attached to individual items, boxes, or pallets. RFID readers located at various points within the warehouse read the data contained in the tags, and the system then processes this information to help companies track inventory in real-time.

A comprehensive guide to RFID for warehouse operations management. 08 August 2022. 9 min read. Radio Frequency Identification (RFID) refers to a wireless system comprised of two components: tags and readers.

Operational efficiency stands at the core of successful warehouse management, and RFID technology serves as a catalyst in this domain. The instantaneous data capture from RFID tags bypasses the need for manual data entry, . RFID tags can be attached to high-value items, and the system can immediately detect unauthorized movement. This feature acts as a deterrent for potential thieves and helps maintain the integrity of the warehouse. Challenges in .By using RFID tags to track items, warehouses can improve their efficiency and accuracy. This guide will teach you how to decide if an RFID system is appropriate for your warehouse and how to implement it successfully.

rfid warehouse tracking system

Tags, labels, and inlays are the fundamental building block of any RFID solution. Between passive or active, a range of frequencies, label specs, and environmental conditions there is a lot to evaluate when finding the right label. Learn More.

rfid warehouse tracking

sparkfun nfc reader

python nfc read

rfid warehouse management system requirements

20pcs NFC Cards Rewritable NFC Tags NTAG 215 PVC Cards Blank Easy Convenient .

warehouse rfid tags|rfid system for warehouse management